As cars get smarter and more connected, it’s important to ensure the integrated circuits (ICs) they depend on are reliable. A small malfunction can lead to serious safety risks and costly recalls. AEC-Q100 provides strict standards that help manufacturers meet performance and regulatory requirements in automotive electronics.

This blog post shows why AEC-Q100 reliability testing is important for keeping your products safe and trusted. It explains how knowing these standards can help your business succeed and keep drivers safe on the road.

What is AEC-Q100?

AEC-Q100 is a set of challenging tests to ensure that the computer chips (or integrated circuits) in cars are strong and reliable, even in challenging conditions like extreme heat, vibrations, and electrical interference. Since cars are exposed to these conditions, it’s important that the chips can handle them without failing.

The AEC-Q100 standard was created by the Automotive Electronics Council (AEC), a group of major U.S. car manufacturers, to ensure that electronic parts in cars meet high-quality and safety standards. The AEC also developed other standards, such as AEC-Q101 for transistors and AEC-Q102 for light-based components like sensors.

What Does AEC-Q100 Test?

AEC-Q100 checks how strong and reliable chips (or integrated circuits) are to ensure they can handle the tough conditions in cars. Here’s what it tests:

1. Temperature Changes: Cars can experience rapid temperature shifts, like moving from a hot car interior to a cold environment. AEC-Q100 tests whether the chip can survive and function properly after such quick temperature changes.

2. Long-Term Heat: Since cars can get hot, especially under the hood or in direct sunlight, the test checks if the chip can keep working after being exposed to high heat for long periods, without failing or losing performance.

3. Humidity: Cars often face moisture from rain, humidity, or condensation. AEC-Q100 testing checks if the chip can handle this moisture without getting damaged or corroded, so it keeps working properly.

4. Shocks & Vibration: Cars experience constant bumps and vibrations, especially on rough roads. This test checks if the chip can handle physical shocks and constant vibrations typically experienced in cars.

5. Static Electricity: If a chip passes these difficult tests, it gets the AEC-Q100 certification, showing it’s strong and dependable enough to be safely used in cars.

AEC-Q100 ensures that car electronics are safe and reliable, preventing failures that could put your safety at risk.

The Critical Role of AEC-Q100 in Automotive IC Reliability

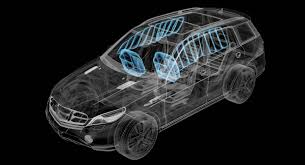

AEC-Q100 is a key testing standard created by the Automotive Electronics Council to ensure the tiny but important chips in cars are safe and dependable. These chips control crucial systems like brakes, airbags, and driver-assistance features, so they must be able to handle harsh conditions like extreme heat, vibrations, and moisture without failing.

1. Safety and Performance: The chips control vital systems like braking and airbag deployment. If a chip fails, it could cause serious problems. AEC-Q100 testing ensures these chips can handle real-world conditions, so they perform safely and reliably when needed.

2. Industry Compliance: Car manufacturers and suppliers require AEC-Q100 compliance to ensure the parts meet high standards of quality and reliability. It also aligns with global safety regulations, like ISO 26262, to keep automotive electronics safe.

3. Consumer Expectations: Today’s drivers want their cars to be safe, tech-savvy, and long-lasting. AEC-Q100 helps ensure that the chips in vehicles meet these demands, contributing to better performance and reliability over time, which builds consumer trust in both the technology and the car brand.

AEC-Q100 testing is important because it ensures that the chips used in cars are strong, dependable, and safe. This helps protect drivers and keeps vehicles running smoothly.

Key Testing Procedures and Requirements in AEC-Q100

AEC-Q100 ensures that automotive-grade chips (ICs) can withstand the tough conditions found in vehicles, making them reliable, durable, and safe for use in cars.

Key Tests:

1. Temperature & Humidity Tests: THB (Temperature-Humidity Bias) and HAST (Highly Accelerated Stress Test) create hot and humid conditions to see if the chip can resist corrosion and avoid failures in these extreme environments.

2. ESD & Latch-Up Tests: Simulate electrical shocks to ensure the chip can withstand static discharges and prevent short circuits, which can cause device malfunctions.

3. High-Temperature Operating Life (HTOL): Tests the long-term durability of chips under high heat and voltage, predicting the aging effects and how they’ll perform over time.

4. Shock & Vibration Tests: These tests simulate physical impacts and road vibrations to ensure the chip stays intact and its connections remain reliable, even in tough driving conditions.

5. Other Tests:

Thermal Cycling/Thermal Shock: Checks the chip’s resistance to sudden and extreme temperature changes, ensuring it can handle quick shifts in climate.

Burn-In: This test puts the chip through extreme conditions to catch early issues, ensuring that only the most reliable chips are released to the market.

The Business and Strategic Value of AEC-Q100 Testing

Meeting the AEC-Q100 standard is a strategic move for automotive electronics manufacturers. It builds trust, minimizes risks, and helps companies stand out in the competitive automotive industry.

Fewer Failures and Recalls

AEC-Q100 testing puts chips through tough conditions to find problems before they reach the market. This lowers the risk of failures in real cars, helping manufacturers avoid costly recalls and protect their brand reputation.

Better Supplier Relationships

When a company earns AEC-Q100 certification, it shows they prioritize quality. This builds trust with automakers and suppliers, making them more likely to approve parts quickly and form long-term working relationships.

Competitive Advantage

Getting AEC-Q100 certified helps a company stand out from competitors by proving its chips are reliable and durable. It also allows the company to sell in more markets where this certification is required, helping it grow and reach more customers.

Following AEC-Q100 helps a company reduce future problems, gain trust from major customers, and strengthen its position in the competitive automotive market. It’s not just about passing a test—it’s a smart business strategy for success.

Conclusion: Understanding the Importance of AEC-Q100 Automotive IC Reliability Testing

As automotive technology evolves and vehicles become smarter and more connected, ensuring the reliability and durability of the integrated circuits (ICs) that power these innovations is crucial. A small failure in a chip can have serious consequences, from safety risks to expensive recalls.

AEC-Q100 testing ensures automotive chips can withstand extreme conditions like temperature changes, humidity, vibrations, and electrical shocks. Chips that pass these tests earn the AEC-Q100 certification, guaranteeing their reliability and safety.

This certification helps manufacturers build trust, avoid costly recalls, and meet high industry standards, keeping their products competitive and in line with consumer expectations for safe, high-tech vehicles.

Leave a Reply